|

Ningbo Yinzhou Yifei Machinery Accessories Factory

|

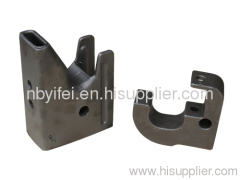

Train Part 3

| Price: | 1.0~100.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Casting Process: Water glass process of lost wax investment casting

Standard: ASTM, AISI, DIN, BS and JIS

Ningbo Yifei Machinery Accessories Factoryis a profiessional manufacturer since 2003, we specialize in manufacturing and supplying a variety of ferrous & non-ferrous castings utilizing sand, investment, die and permanent-mould process with grades of material covering steel, stainless steel, carbon steel, brass, bronze, copper, ductile iron, gray iron, aluminum & its alloys etc.

In our foundry, we have manufacturing facilities and all the necessary equipments to deal with heat treatment and most kinds of machining work like tuming, drilling, grinding, polishing, milling, boring, forging, stamping etc. Different surface treatment is also available, like zinc plating, chrome plating, powdering, lacquering etc. All of our products are exported worldwide.

Size Range

Parts weighing from a few ounces to as much as 155 pounds (5 g. to 70 kg),Sizes up to 0.25" x 25" (.63 m x .63 m)

Tolerances

±.005 inch per inch (±.127 mm) or better

Quality Assurance

All items produced are identified throughout the manufacturing process and can be traced back to the raw material manufacturer:

We have set up a quality control system that meets customers' specific requirements, and perform an internal or external audit to guarantee the efficiency of our system.

Process: sand casting, investment casting/lost wax casting,

Machining capability: CNC Machining Center, CNC Precision Lathe, CNC Drilling and Tapping,

Heat treatment: T6 heat treatment

Surface treatment: polishing, mill finished, machined, sand blasting, powder coat, painting etc.

We manufacture various kinds of casting parts according to your drawings or sample with high-quality, competitive price. We also accept small order.

Our strong R&D and QC department can control the products to meet your strict requirement or ISO9001 standard. And we also offer the engineer consultation to your design for production improvement and cost saving.

Delivery time: 45 days after confirmation of order and drawings.

Applied software for specification drawings: Pro/E, Auto CAD, Solid Work; CAD/CAM/CAE,

Packing: protective, bubble pack, carton, pallet or based on your special requirement

Our products are widely applied and almost covered all applicable fields that involves equipment manufacturing & mechanical manufacturing industries, mainly including trains and railways, mining and engineering machinery, automobile, ships, petroleum machinery, agricultural machinery, construction, valve and pumps, electric machine ,hardware, power equipment and so on. We produce according to customers' drawings or samples, focus on the material categories of carbon steel and low alloy steel. Up to the present, more than 100 specific material specifications and 3,000 kinds of products have been developed and produced in our company. We are proficient in performing various industrial standards, such as Chinese GB, American ASTM, AISI , German DIN, French NF, Japanese JIS, British BS, Australian AS and Association of American Railroads (AAR )and other industrial standards.

Breaking out of the traditional practice that foundries only provide OEM castings, our company has created the new sale concept whose main points are providing solutions, terminal products and customer services. We focus on the developing for high-quality products and top-end markets, striving to increase products' added value for its core competitiveness. Except for domestic supply, our products are mainly exported to foreign markets, which including over 30 countries such as USA, Germany, Japan, Spain, Italy, UK, France, Holland, Australia and Canada. And the company has already made co-operations with more than 10 out of the World Top 500 companies as one of their major casting suppliers in China.

Our company strategic: "leading development in this industry, striving to found a great casting enterprise with core competitiveness and core value", confirmed with "leading with the ideas, equipments, QC, services" as its core competitive capability. It sticks to the quality management philosophy that "it starts from the need of customers and ends with their satisfaction, regards customers as its center and transcends their expectations". With the enterprise spirit of “keeping paces with times, pioneering and innovating, harmony and win-win, striving for excellence”, and base on the working-style of “honesty and practicalness, persevering unremittingly, teamwork spirit, struggling and exceeding”, our company would like to sincerely invite the global prospective buyers to pay a visit and have a good cooperation for a splendid future together.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Wooden Train

Train Set

Electric Train

Aluminum Train Case

Wooden Train Blocks

Wooden Train Set

More>>